Projects

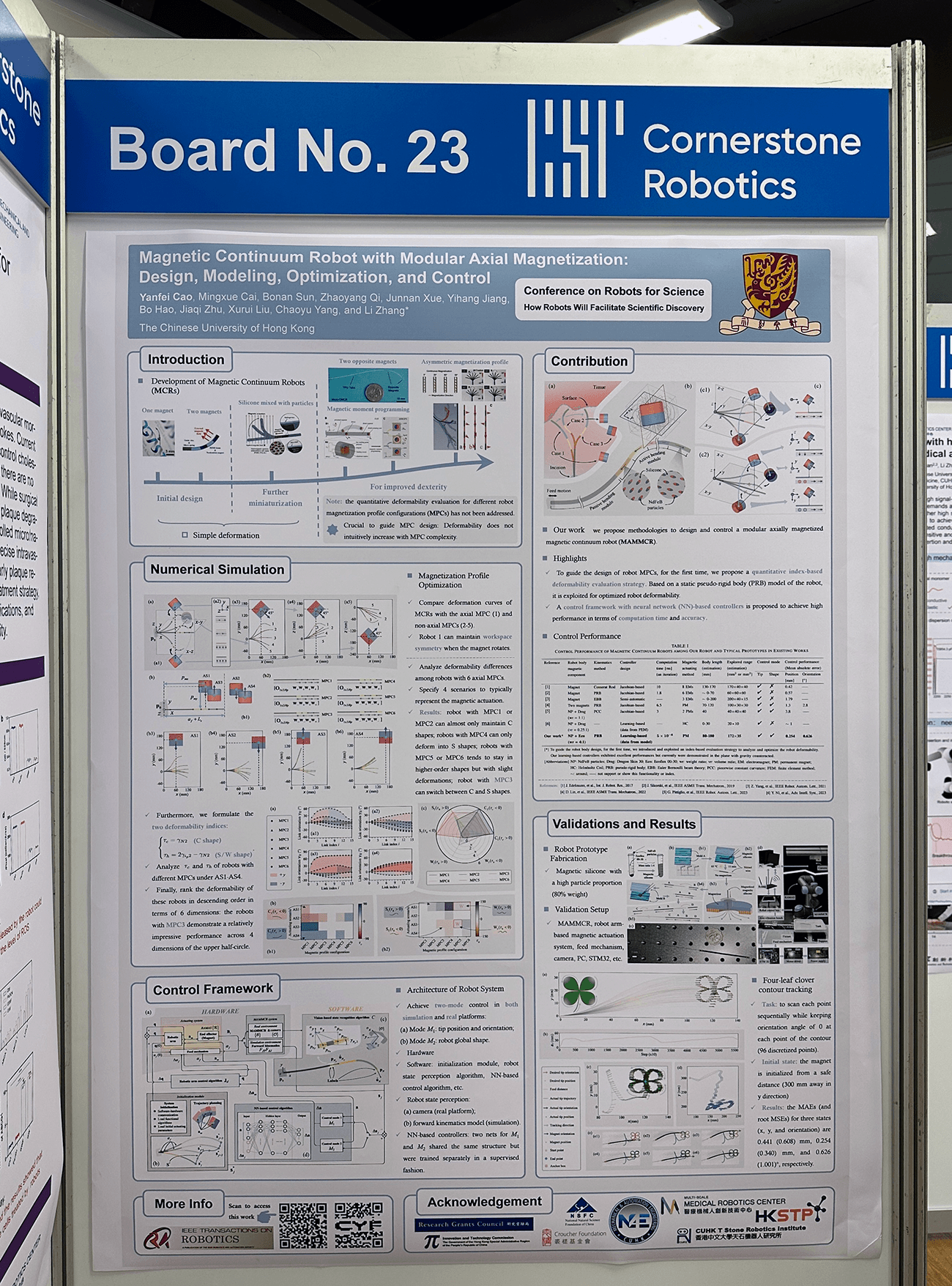

Magnetic Continuum Robot with Modular Axial Magnetization: Design, Modeling, Optimization, and Control

Done by Y. Cao, M. Cai, B. Sun, Z. Qi, J. Xue, Y. Jiang, B. Hao, J. Zhu, X. Liu, C. Yang, L. Zhang*.

@ MAE, CUHK, Hong Kong, 2023-2024

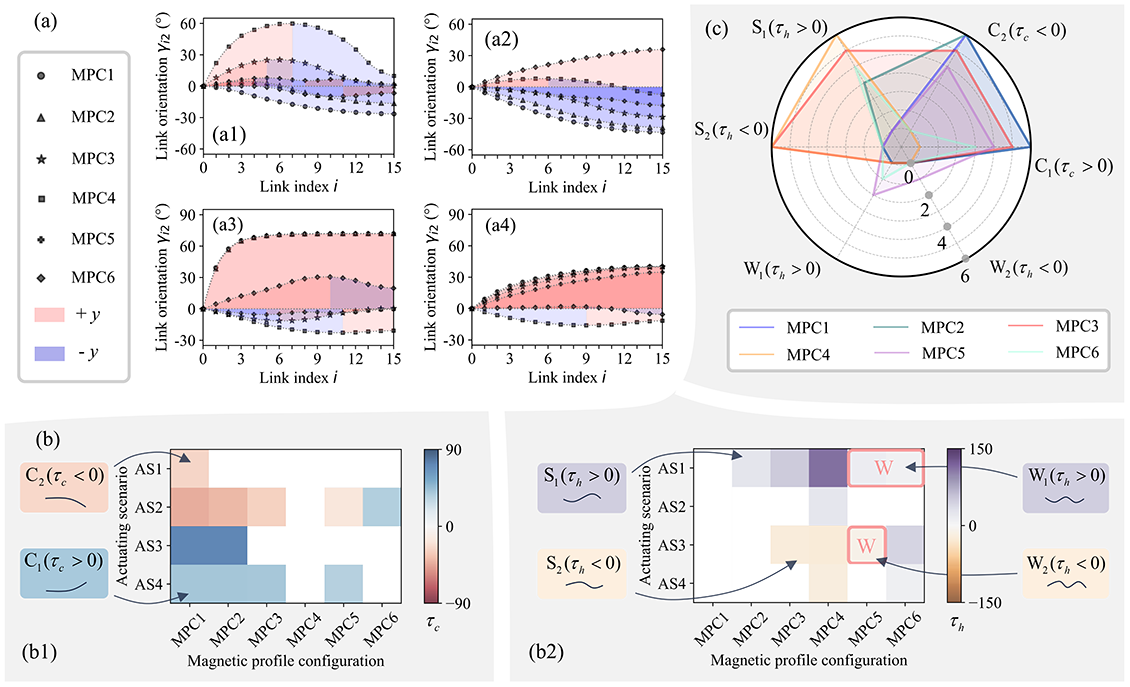

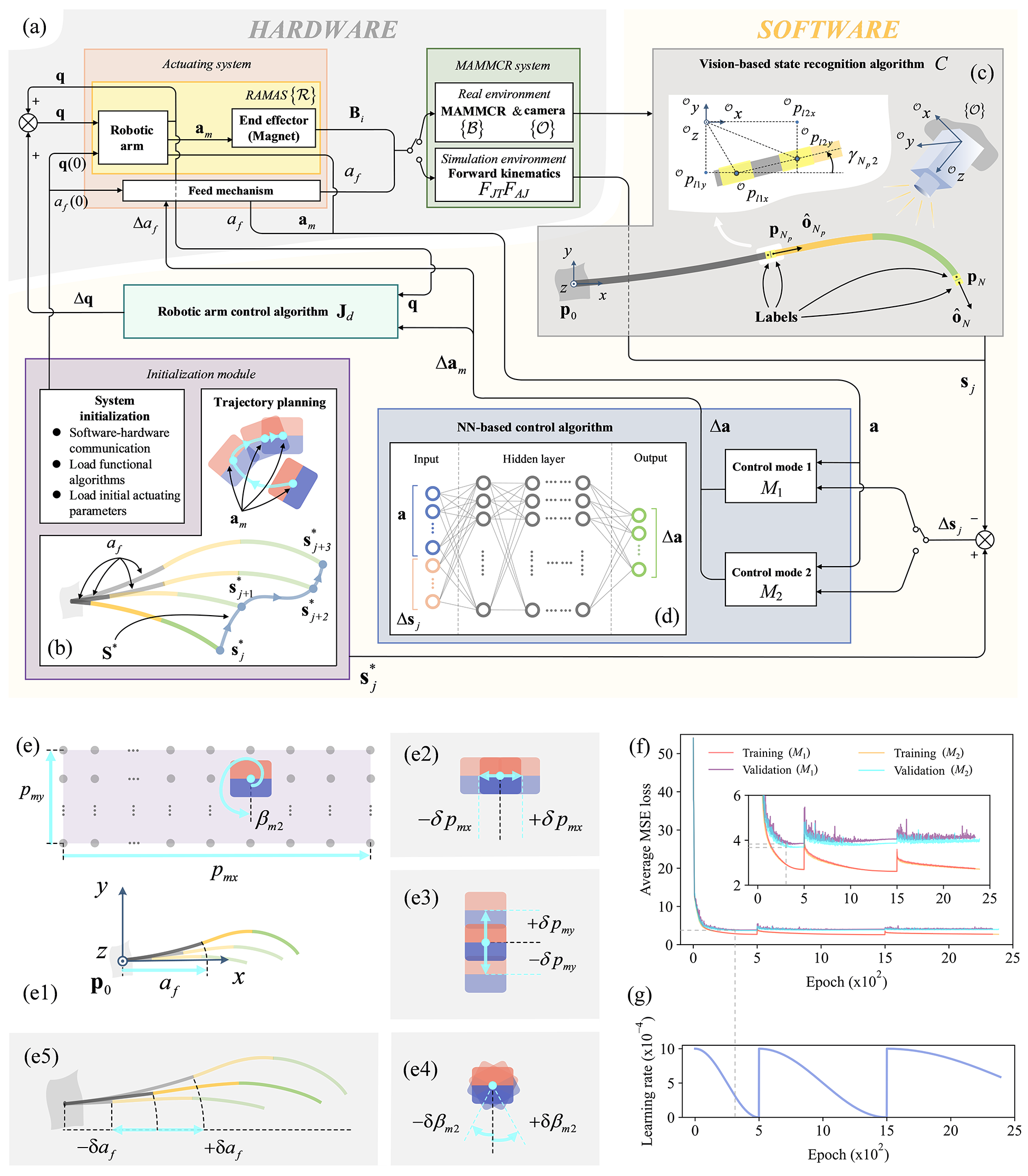

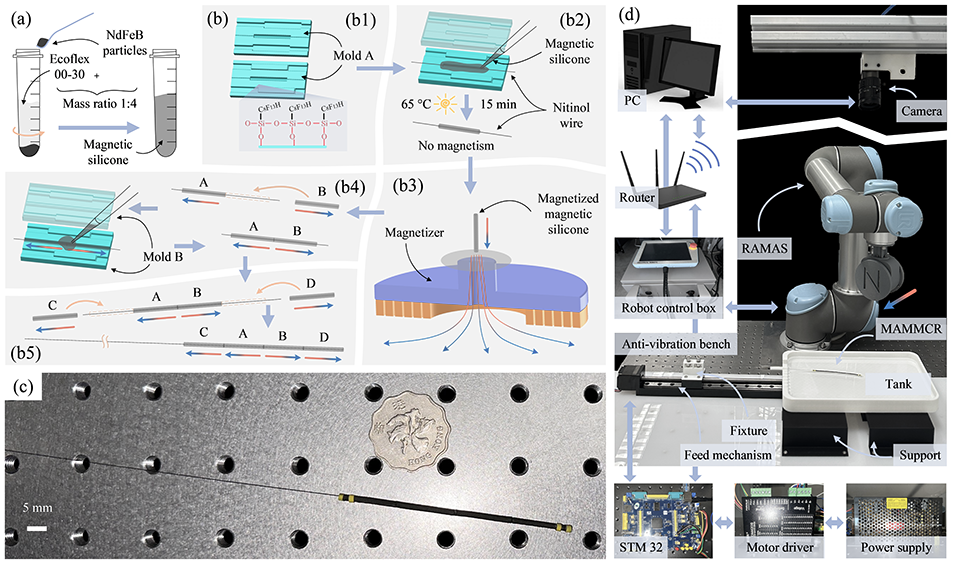

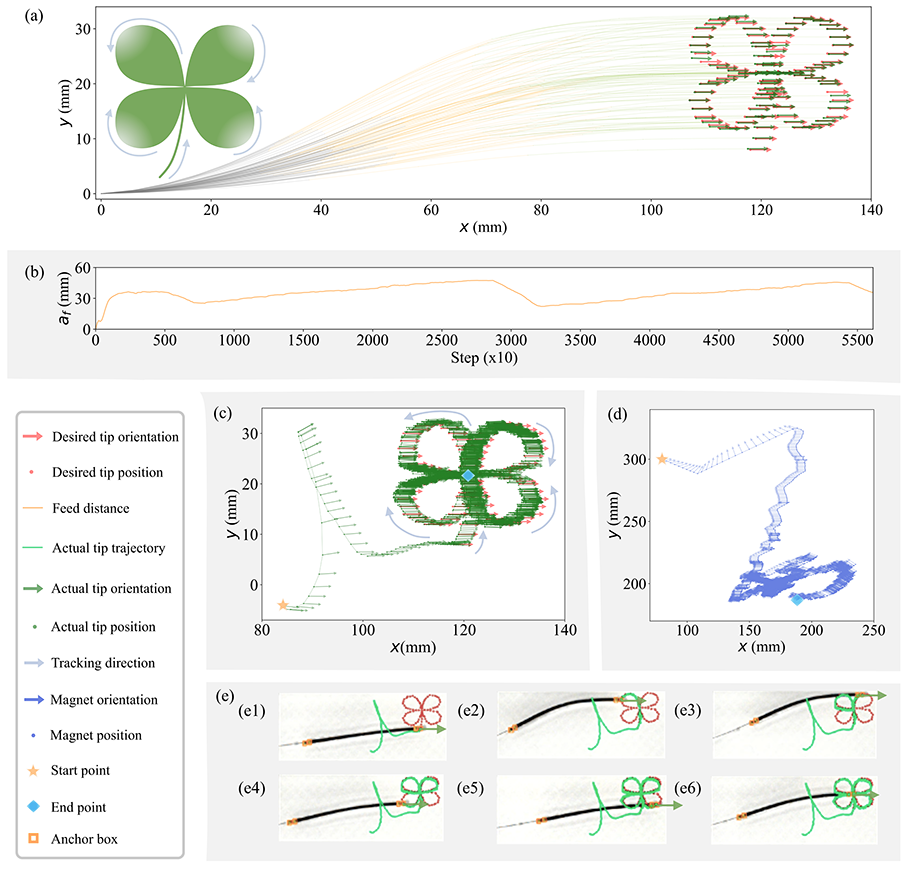

Magnetic continuum robots (MCRs) have become popular owing to their inherent advantages of easy miniaturization without requiring complicated transmission structures. The evolution of MCRs, from initial designs with one embedded magnet to current designs with specific magnetization profile configurations (MPCs), has significantly enhanced their dexterity. While much progress has been achieved, the quantitative indexbased evaluation of deformability for different MPCs, which can assist in designing MPCs with enhanced robot deformability, has not been addressed before. Here we use "deformability" to describe the capability for body deflection when an MCR forms different global shapes under an external magnetic field. Therefore, in this paper, we propose methodologies to design and control an MCR composed of modular axially magnetized segments. To guide robot MPC design, for the first time, we introduce a quantitative index-based evaluation strategy to analyze and optimize robot deformability. Additionally, a control framework with neural network-based controllers is developed to endow the robot with two control modes: the robot tip position and orientation (M1) and the global shape (M2). The excellent performance of the learnt controllers in terms of computation time and accuracy was validated via both simulation and experimental platforms. In the experimental results, the best closed-loop control performance metrics, indicated as the mean absolute errors, were 0.254 mm and 0.626° for mode M1 and 1.564 mm and 0.086° for mode M2.

This work has been published online in IEEE Transactions on Robotics. LINK(🔥Highlighted in 机器人大讲堂)

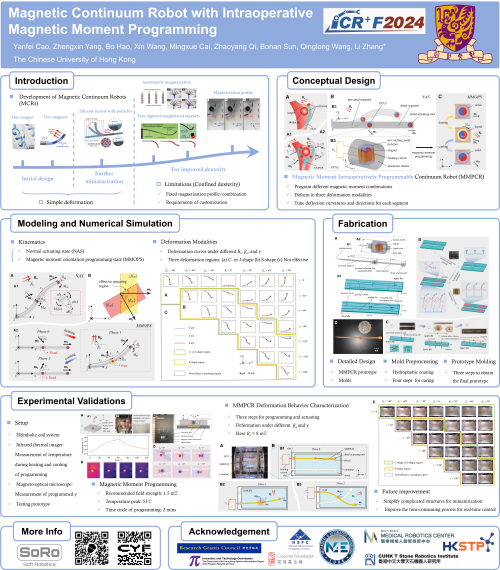

Magnetic Continuum Robot with Intraoperative Magnetic Moment Programming

Done by Y. Cao, Z. Yang, B. Hao, X. Wang, M. Cai, Z. Qi, B. Sun, Q. Wang, L. Zhang*.

@ MAE, CUHK, Hong Kong, 2022-2023

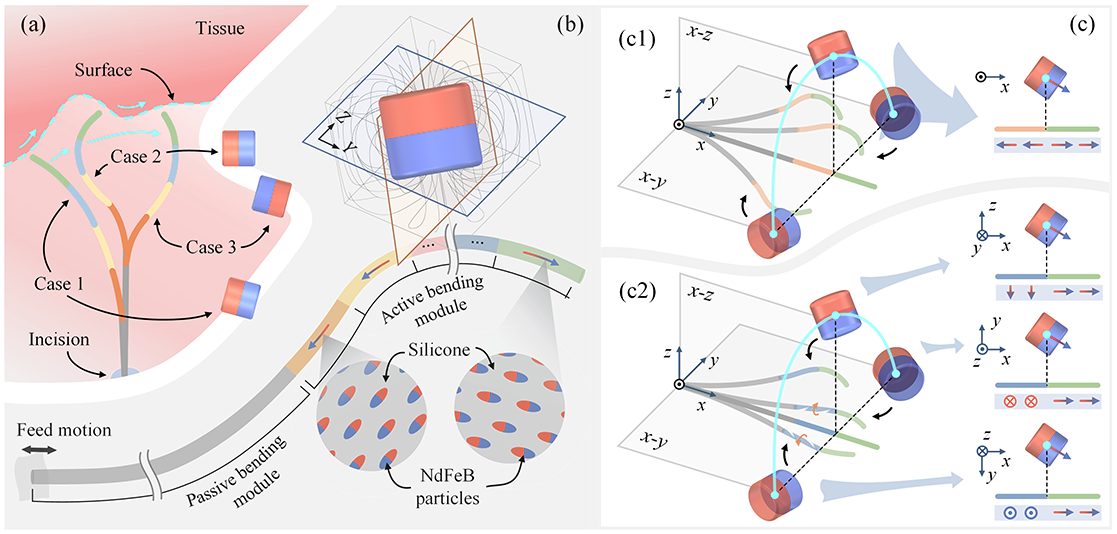

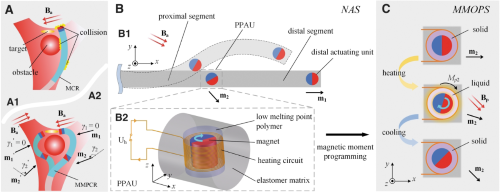

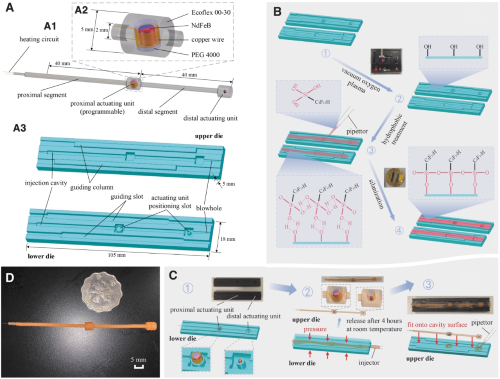

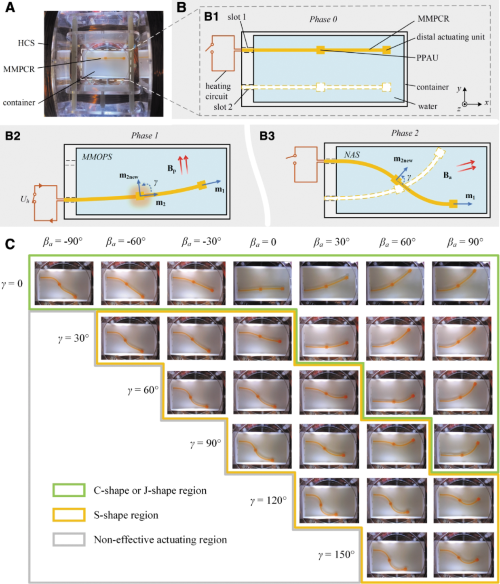

Magnetic continuum robots (MCRs), which are free of complicated structural designs for transmission, can be miniaturized and are therefore widely used in the medical field. However, the deformation shapes of different segments, including deflection directions and curvatures, are difficult to control simultaneously under an external programmable magnetic field. This is because the latest MCRs have designs with an invariable magnetic moment combination or profile of one or more actuating units. Therefore, the limited dexterity of the deformation shape causes the existing MCRs to collide readily with their surroundings or makes them unable to approach difficult-to-reach regions. These prolonged collisions are unnecessary or even hazardous, especially for catheters or similar medical devices. In this study, a novel magnetic moment intraoperatively programmable continuum robot (MMPCR) is introduced. By applying the proposed magnetic moment programming method, the MMPCR can deform under three modalities, that is, J, C, and S shapes. Additionally, the deflection directions and curvatures of different segments in the MMPCR can be modulated as desired. Furthermore, the magnetic moment programming and MMPCR kinematics are modeled, numerically simulated, and experimentally validated. The experimental results exhibit a mean deflection angle error of 3.3° and correspond well with simulation results. Comparisons between navigation capacities of the MMPCR and MCR demonstrate that the MMPCR has a higher capacity for dexterous deformation.

This work has been published online in Soft Robotics. LINK

Employment Experience

Module Development and Maintenance of Failure Mode and Effects Analysis (FMEA)

Software Engineer

@ Department of Information and Communication Technology, HUAWEI, Nanjing, 2019-2021

I joined HUAWEI as a software engineer when I achieved the M. Sc. degree in NUAA. The team I served for supports a bunch series of HUAWEI's core products, like high-end communication devices named "NetEngine 8000 Series Routers" and stuff. I was mainly in charge of module development and maintenance of FMEA, related to periodically monitoring hardware failure and reporting alarms during equipment running. This assured the stability and reliability of equipments without impairing performance.

Over the two years or so, I have delivered 15+ product iterations on developing new software requirements, during which I served as iteration owner. Meanwhile, I solved 500+ defect tracking sheets (DTS) and was honored with Gold Network Award for 3 times.

Conferences and Symposiums

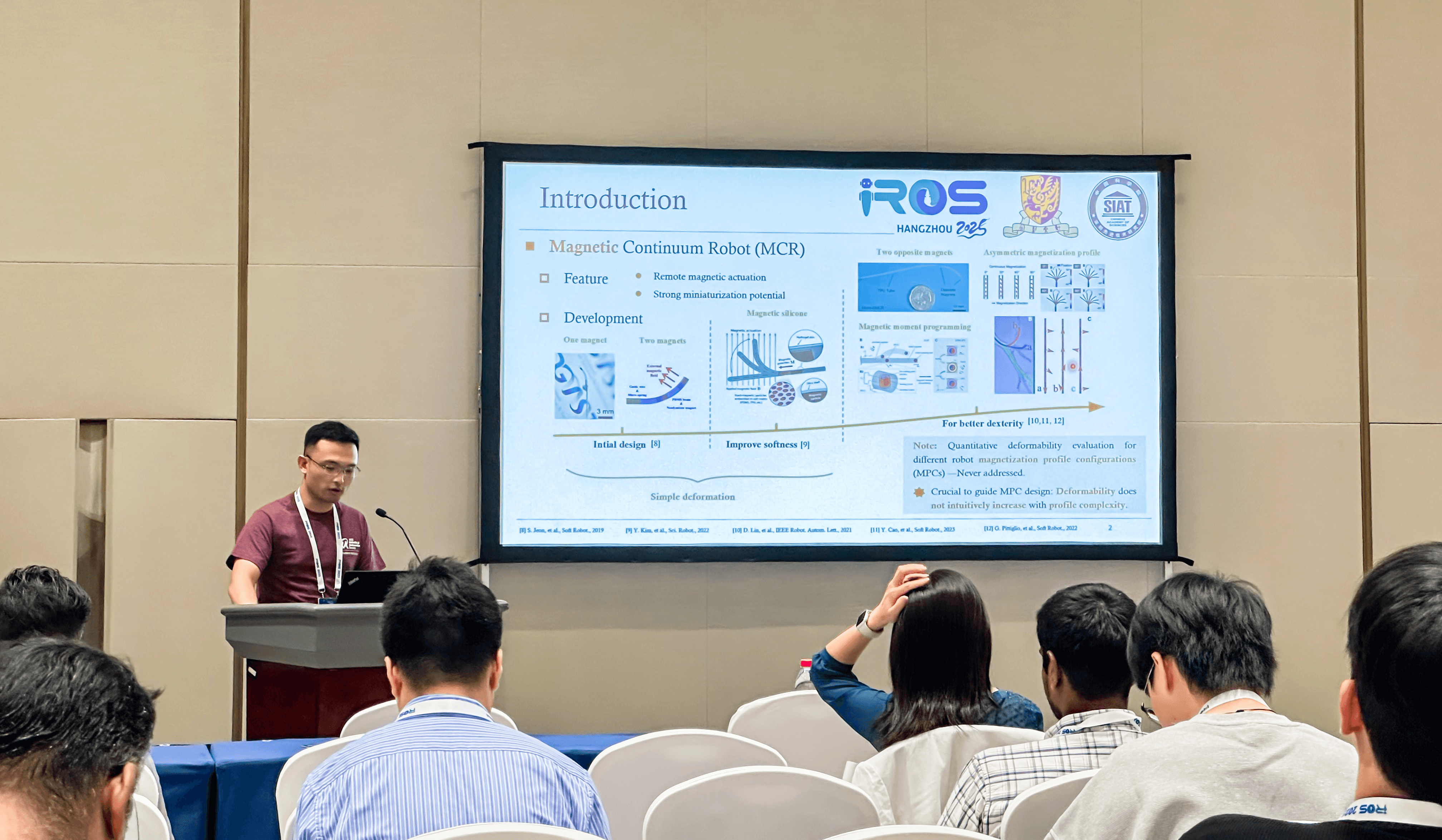

The 2025 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2025)

@ Hangzhou, 19-25 Oct 2025

Conference on Robots for Science–How Robots Will Facilitate Scientific Discovery

@ Hong Kong, China, 15-17 Jan 2025

18th International Conference on Biomedical Engineering (ICBME 2024)

@ Singapore, 09-12 Dec 2024

2024 DGIST International Collaboration Symposium

@ Daegu, South Korea, 18-21 Nov 2024

2024 International Conference of Robotics+Frontiers Technology (ICR+F 2024)

@ Suzhou, China, 28 June-01 July 2024

2018 International Academic Conference for Graduates, NUAA (IACGN, 2018)

@ Nanjing, China, 18-19 October 2018

Honored with Best Paper Award in 2018 IACGN

Research Grant

-

Member. Research on a Reconfigurable Robot System for Intracardiac Artery Intervention. PI: Prof. Bai Chen. National Natural Science Foundation of China. No. 51575256, 640,000 RMB, 2016-2019. 中国国家自然科学基金, 可重构的心动脉内介入手术机器人系统研究.